Key stuff you must realize approximately an MRP System

An MRP System (Materials Requirements Planning) facilitates a production employer to make use of integrated scheduling common sense to manipulate the glide of substances withinside the production operation. Companies are searching for methods to lessen stock costs, power down lead instances at the same time as enhancing patron service, enhance the producing manner and enhance product exceptional. Using an MRP machine, a producer can grow to be a good deal greater green and higher plan the wishes for resources, each in phrases of substances in addition to capability withinside the manufacturing unit and higher serve the patron.

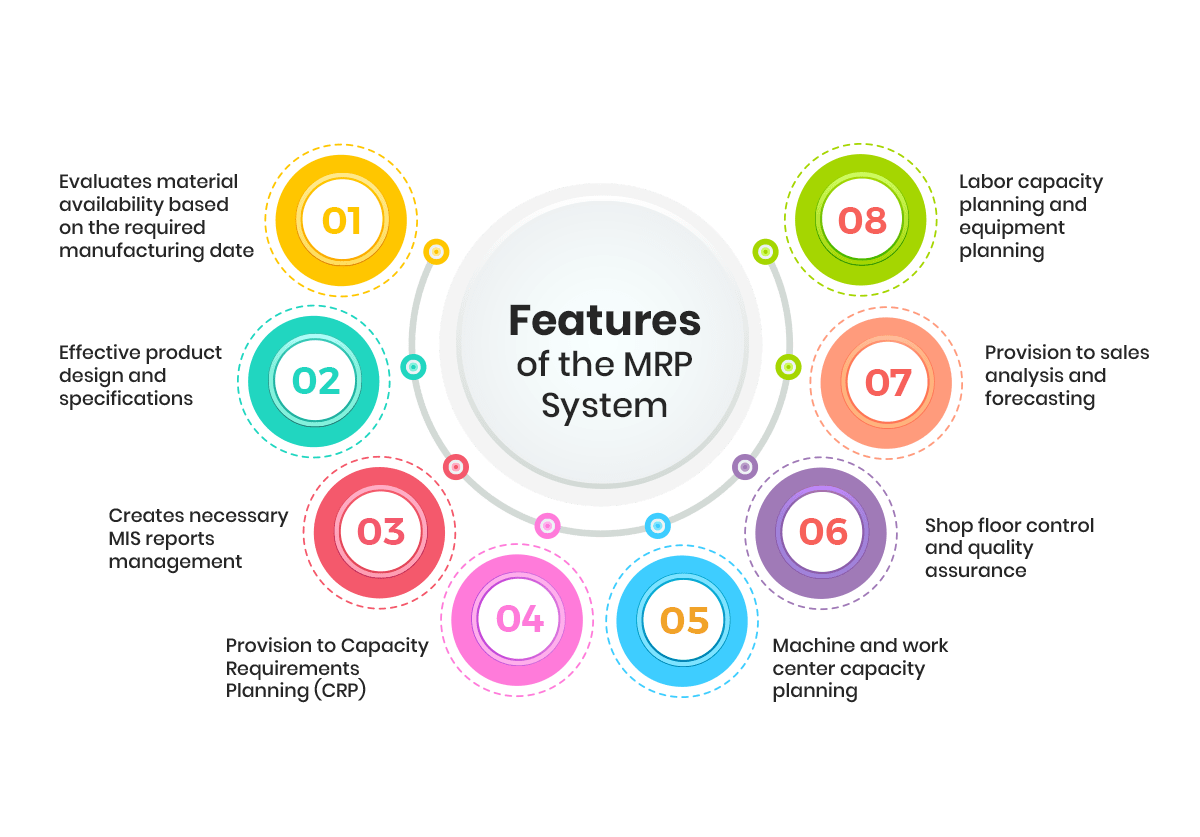

There are forms of MRP Systems that may be discussed. The first is Material Requirements Planning and the second one is Manufacturing Resource Planning or MRPII. A conventional MRP System is one in which the software program makes use of the Bills of Materials, Inventory levels, and the Master Production Schedule to calculate and plan the want for replenishment orders. An MRPII machine is a machine that plans many greater capabilities of the whole production manner, which includes Capacity Requirements making plans, Master Production scheduling, Plan Simulations, and all of the factors of the conventional MRP machine.

Most structures nowadays are MRPII primarily based totally structures, so from this factor forward, if we’re regarding an MRP System, we’re clearly discussing MRPII structures as that’s what is currently provided withinside the marketplace and consists of the sooner factors of MRP.

Researching an MRP System regularly brings approximately numerous questions and uncertainty. Not a lot approximately the making plans machine and the way it calculates the necessities, this is generally only a calculation that you may get from a very good Material Requirements Planning ee-ebook from any book place or online. Really, the query generally comes approximately as to in which the variations are among the fabric necessities making plans structures.

Essentially, the important thing differentiators of those structures will be the ease in their capacity to can help you see a couple of layers of making plans. But even greater, the benefit wherein you may preserve the records easily. With heaps of elements and in all likelihood heaps of Bills of Materials (alongside the various variations), you’ll want for you to without difficulty replace or maybe mass replaces elements, BOMs, routings, and all the elements surrounding them.

MRP System as a part of an ERP solution

As the maximum production machine software program is a subcomponent of ERP (Enterprise Resource Planning), it’s miles really well worth searching at how the substances making plans issue of the ERP interacts with the relaxation of the machine. For example, how nicely does the machine talk order necessities to the store ground manage machine? How nicely does the Product Data Management issue of the ERP engage with the Bills of Material module? How nicely does the stock manage machine paintings with the Quality Management machine? For example, in case you acquire stock into the machine, is there a manner to isolate it from the MRP System at the same time as it undergoes exceptional inspections?

When searching at necessities making plans structures the actual situation is how the customers will use it. It wishes to be as easy as feasible to engage with from a personal perspective. However, it wishes for you to power all the capability and fabric plans which you want to run the business. A critical issue to attempt is to allow your fabric making plans or buying humans to attempt out the machine at some point of the demo phase. They might not be capable of running the machine without assistance, however, at a minimum, they could get experience with the monitors and the intensity of facts provided.

Another critical tip is to ensure that every one of your folks who are interacting with the machine, which include buyers, planners, and stock managers all have education at the standards of MRP. This will assist them to arise to hurry quickly as soon as a brand new machine is in place.

Your Future MRP System

When you get right all the way down to a brief listing of vendors, it’d be an extremely good concept to begin searching on the exceptional facts out of your current MRP System. Clean up the Bills of Materials. Obsolete any which might be out of date. Ensure that your stock counts are accurate. Make positive that your patron orders are easy and antique back-orders so that it will by no means deliver are closed. You must start the cleanup of the records withinside the supply machine lengthy earlier than you even reflect on consideration on shifting it to the brand new machine. If you do it touch at a time over a duration of months, by the point you’re prepared to emigrate the records to the brand new machine, you may be prepared to make use of the brand new machine immediately. At a few factors the records wish to be easy, it would as nicely be now.

Lastly, discover early from the software program company of the brand new machine what extra records factors you’ll want to aid their machine. You might not be taking pictures that record currently, so begin constructing the listing now. Moving to a brand new MRP machine does now no longer wants to be difficult, however, it’s going to take a few cleanups and making plans.

What in case you can’t make a selection on an MRP solution?

We realize how tough it’s miles to try to make a software program choice to your own, however in case you need to clearly achieve success and select the suitable in shape software program on your organization, you’ll want to locate the proper pointers that will help you achieve success.

These techniques are easy to select out up and that does not take numerous learning. You can study the way to do it in our unfastened file on ERP Selection, the ERP Software Buyers Guide.